The tool I needed for dimpling the flap skins rivet holes arrived last Friday. I was able to dimple the holes successfully with the new tool on Monday (05/03/10)

The tool I needed for dimpling the flap skins rivet holes arrived last Friday. I was able to dimple the holes successfully with the new tool on Monday (05/03/10)After dimpling, I corrosion proofed the skins and ribs with a Zinc Phosphate primer I purchased from Aircraft Spruce. I cleaned the surface with alcohol to remove any oils or contaminates prior to spraying on the paint. The paint/primer meets Federal Specification T-P-1757A for corrosion protection.

Today, I took the first steps in final assembly by Cleco-ing together the flap spar, spar doubler, ribs, & nose ribs. The assembly instructions say to rivet the pieces together using the hand squeezer.

With the jaws I have I can not reach around the spar with the squeezer, so I ordered a "C" riveting tool that will attach to the pneumatic rivet gun. The tool should be here by this week end when I am off again.

I found the AN470AD-4-5 rivets were too long and the AN470AD-4-4 rivets were too short. I trimmed the -4-5s down a little with the rivet cutting tool.

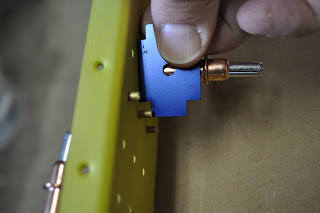

Here I am using the rivet length measuring tool to trim the rivet to proper length for riveting.

Here are the rivets, an AN470AD-4-5 untrimmed and one that has been cut in the cutting tool.

This up coming weekend I will be off and should be able to start riveting the assembly together.

Later,

BWW

No comments:

Post a Comment